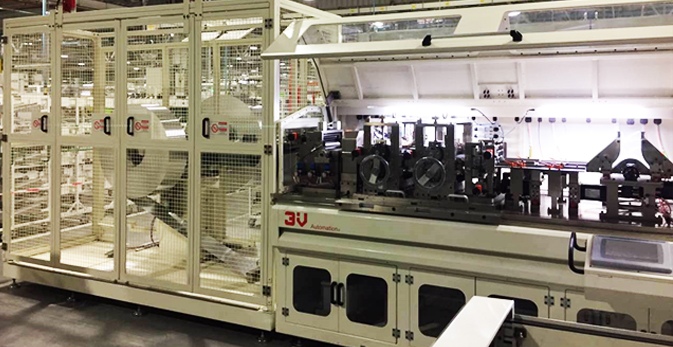

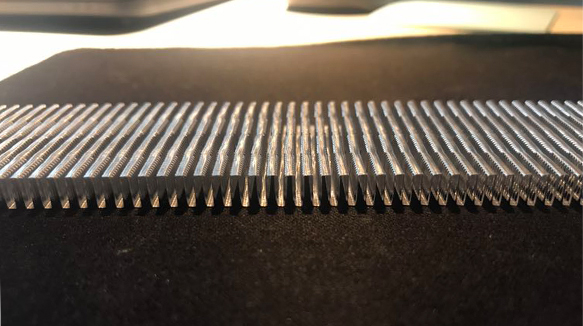

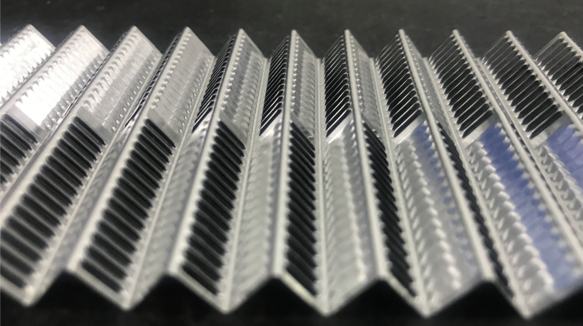

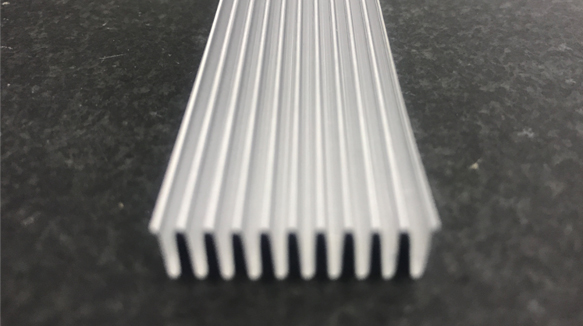

FIN FORMING MACHINE

3V fin machines are a key part of our business working worldwide. These flexible, quick change machines are capable of producing state of art fins with flat top, extended louvers combined with low gauge material thickness. The fine tooling can be exchanged. Controlled by PLC and touch screen, it can be connected with automatic production line. 3V fin machine family includes single track fin mill, twin fin mill and turbulator fin mill. 3V fin machines are proven to be the best choice for increasing utilization and energy efficiency.

COMPACT CORE BUILDER

- Input speed Max300m/min

- Cutting rate80 cuts/min

- Fin width12mm - 110mm

- Fin height4 -10mm

- Strip thickness0.05-0.16mm

- Fin half-period0.6 - 2.6mm

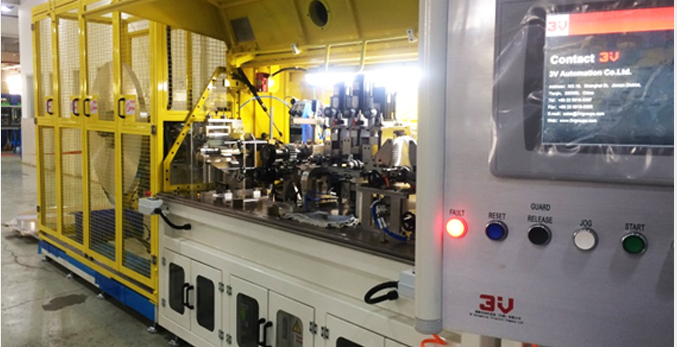

TWIN TRACK FIN MILL

- Input speed Max300 × 2 m/min

- Cutting rate80 × 2 cuts/min

- Fin width24mm-110mm

- Fin height4 - 8mm

- Strip thickness0.05-0.1mm

- Fin half-period0.6-2mm

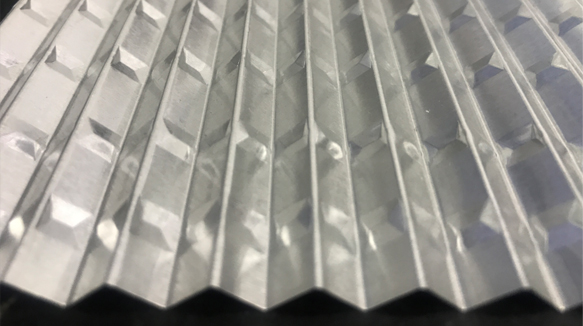

TURBULATOR FIN MILL

- Input speed Max250m/min

- Cutting rate140 cuts/min

- Fin width30mm -120mm

- Fin height4-10mm

- Strip thickness0.06-0.16mm

- Fin half-period0.6-2.9mm

- Input speed Max135m/min

- Cutting rate180 cuts/min

- Fin width64mm - 250mm

- Fin height4 - 10mm

- Strip thickness0.06 - 0.16mm

- Fin half-period0.6 - 2.9mm

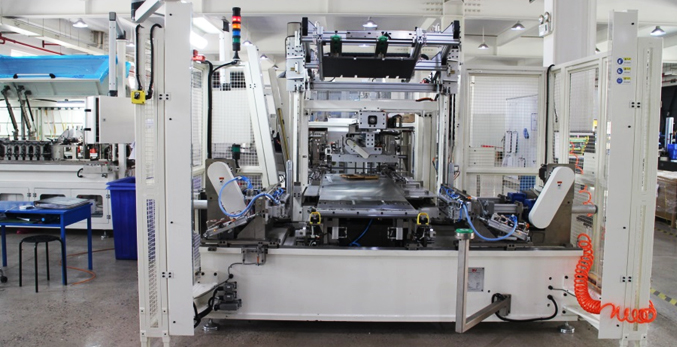

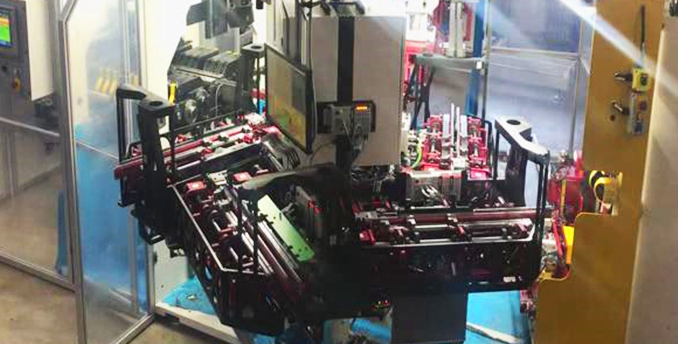

CORE BUILDER MACHINE

3V Core Builder Machines provide solutions to meet all your requirements with market leading flexibility and efficiency. Our Core assembly systems are available to produce Condensers, Radiators, Heaters, Charge Air Coolers, Evaporators and so on. 3V supplies our Core Bulider Machines all over the world and is helping our clients minimize downtime, significantly increase output and saving labor cost.

COMPACT CORE BUILDER

- Radiator Condenser Heater Charge Air Cooler Evaporator

- Header to header

- 300mm-850mm/300mm-1000mm/500mm-1200mm

- Side to side 100mm-850mm/100mm-900mm/500mm-1200mm

HEAVY DUTY CORE BUILDER

- Radiator, Condenser, Charge Air Cooler

- Header to header

- 300mm-850mm/300mm-1000mm/500mm-1200mm

- Side to side 100mm-850mm/100mm-900mm/500mm-1200mm

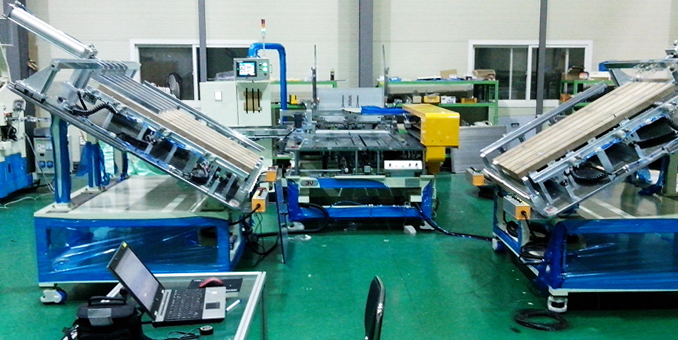

DOUBLE STATION CORE BUILDER

- Heater, Evaporator

- Header to header 150mm-350mm

- Side to side 100mm-300mm

SEMI CORE BUILDER

- Radiator, Condenser, Heater, Charge Air Cooler, Evaporator

- Header to header 300mm-850mm

- Side to side 350mm-850mm

HVAC

- ·Economical

- Reduced raw material costs

- Less labor cost

- Optimized production times

- Higher precision manufacturing

- Reduction of waste raw materials

- ·Technical

- Heat transfer and thermal performance improved

- 20% lower air side pressure drop

- Refrigerant charge reduced

- 50% reduction of coil weight

- Increased reliability due to corrosion resistance